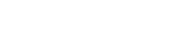

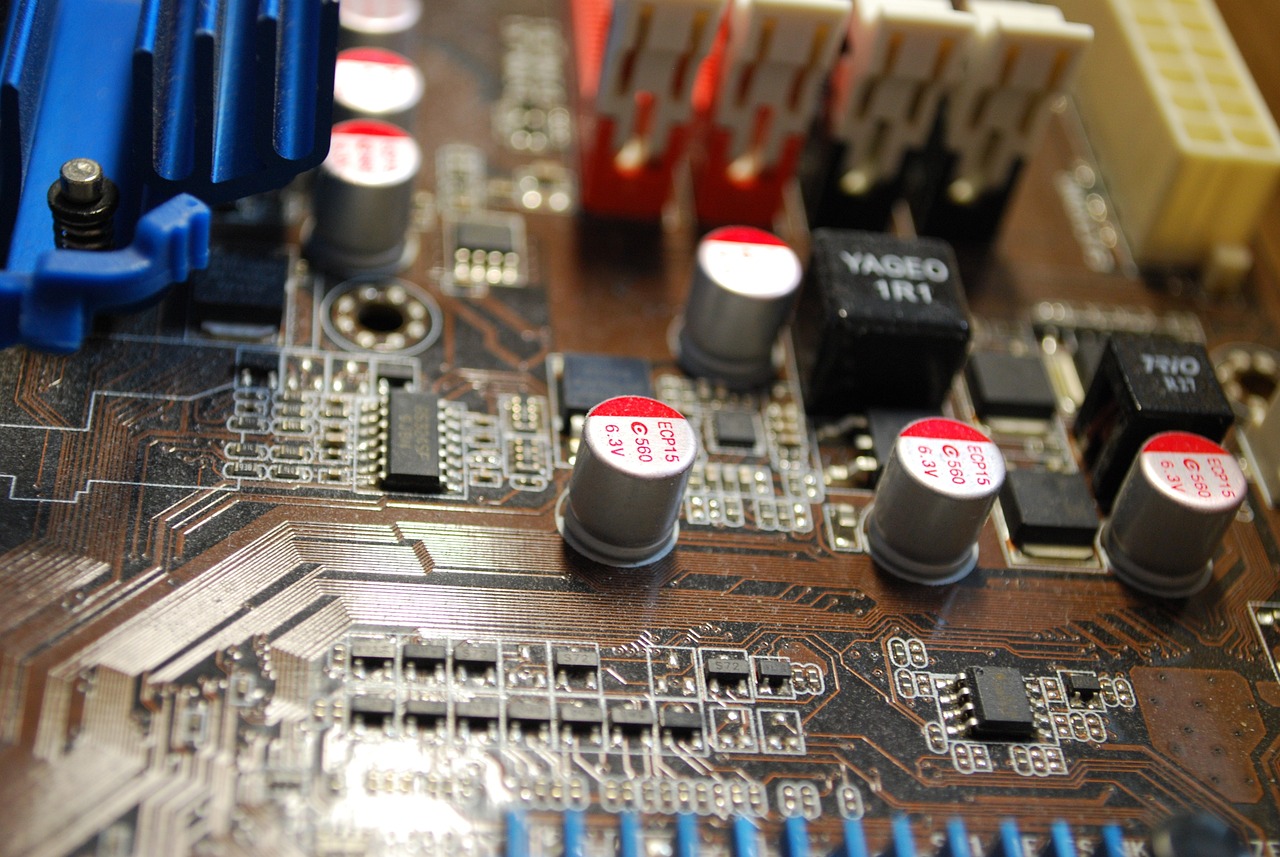

Energy storage plays a crucial role in modern electronics, enabling devices to function efficiently and reliably. Among the various energy storage solutions, capacitors and supercapacitors stand out due to their versatility and unique properties. A capacitor is a passive electronic component that has the ability to store and release energy very quickly, making it essential in countless electronic circuits such as power supply filtering, voltage regulation, and energy storage in low power systems. They consist of two conductive materials separated by an insulating material named dielectric. When a voltage is applied, electric charges accumulate on the conductive materials, storing energy. Several types of capacitors are available on the market, typically classified by the dielectric material they use, such as film, ceramic, and electrolytic capacitors. Depending on the dielectric material, its thickness, and the available area, these capacitors can offer a wide range of capacitance values, voltage ratings and operating temperature ranges, allowing them to meet different requirements for various applications. Film and ceramic capacitors are nonpolar meaning they can be connected in either direction. In contrast, electrolytic capacitors are polarized, meaning their positive terminal is predetermined and must be connected accordingly. Electrolytic capacitors are distinctive in that their dielectric is formed by growing an oxide layer directly on the anode, which is typically made of aluminum or tantalum metal foil. This oxide layer acts as a one-way insulator, defining the polarized nature of these capacitors. An electrolyte, whether liquid, solid or a combination interfaces with the oxide layer and a separated metal foil which acts as the cathode. This unique construction allows electrolytic capacitors to achieve high capacitance values compared with other capacitor types, making them ideal for applications where energy in a compact size is required.1 Among electrolytic capacitors, we can find aluminum electrolytic capacitors (AECs), tantalum electrolytic capacitors and niobium electrolytic capacitors. AECs are considered the most cost-effective, owing to the abundance of aluminum and well-established manufacturing processes. Moreover, they present good stability and long service life allowing operation within this range of temperature. Tantalum capacitors, while more expensive, offer much higher capacitance/volume efficiency compared to AECs. This is due to the higher dielectric constant of tantalum pentoxide (Ta2O5) which ranges from 10 to 27, compared to aluminum oxide (Al2O3), which ranges from 8 to 10. As a result, Ta2O5 can offer significantly higher capacitance per unit volume. Additionally, the manufacturing process of tantalum capacitors allows for the deposition of an extremely thin layer of the dielectric, further enhancing the capacitance. As a result, tantalum capacitors are highly efficient, providing more capacitance in a smaller volume, making them ideal for applications requiring higher energy density and compact sizes, qualities that are particularly advantageous for printed circuit boards (PCBs). Niobium electrolytic capacitors are made using passivated niobium metal or niobium monoxide, combined with a solid electrolyte such as manganese dioxide (MnO2) or conductive polymer. Niobium pentoxide Nb2O5 has a higher dielectric constant (approximately 41) compared to Ta2O5 allowing similar energy storage capabilities, though at a lower voltage rating. The production process of niobium capacitors closely resembles that of tantalum capacitors, but niobium’s abundance makes these capacitors a more economical alternative to tantalum for certain applications.1 The figure below illustrates different capacitor technologies, including AECs and MLCCs, integrated into a circuit board, highlighting their role in power integrity and energy storage. Supercapacitors, also known as ultracapacitors or electrochemical capacitors, are energy storage devices that bridge the gap between conventional capacitors and batteries, offering performance and technical parameters that are intermediate between the two. They provide fast charge and discharge capabilities that are lower than those of capacitors but significantly higher than those of batteries. At the same time, the energy storage capacity of supercapacitors, while less than that of batteries, is significantly higher than that of traditional capacitors. Supercapacitors comprise current collectors, carbon-based material as the active component of the electrodes, an electrolyte and a separator. The electrodes are built by depositing a carbon-based layer on top of the current collector, namely aluminum. Deposition methods vary but the simpler one requires a slurry of activated carbon, which has a highly porous structure, providing a large surface area for charge storage. This carbon is mixed with conductive materials like carbon black to improve the slurry’s conductivity, and binders and solvents. This mixture is then coated on top of the current collector to form the electrode. Depending on the design, the electrodes are separated by a separator and can be either rolled into a spiral-wound configuration or stacked to maximize surface area while minimizing the physical size. The electrolyte, which can be either water-based or organic, is filled into the cell and absorbed by the separator. When a voltage is applied, the ions in the electrolyte move and accumulate at the interfaces of both electrodes, storing charge and enabling energy storage. This electrostatic charge accumulation occurs at the electrolyte/electrode interfaces and is referred to as the electrical double-layer (EDL), which is the primary storage mechanism in most supercapacitors. Devices using this mechanism are commonly known as electrical double layer capacitors (EDLCs). In addition, if specific materials, such as metal oxides or conducting polymers, are used in the electrodes, supercapacitors also can store energy through pseudocapacitance, a process involving fast, reversible electrochemical reactions on the surface of electrodes. These reactions provide additional charge storage beyond the purely electrostatic mechanism. However such capacitors are generally the focus of academia, with little application in the industry.2 Comparative analysis: Capacitors vs Supercapacitors Conventional capacitors and supercapacitors differ significantly in their performance characteristics. Supercapacitors are notable for their extremely high capacitance, often measured in kilofarads, a scale several orders of magnitude of typical capacitors. However, this high capacitance comes with a trade-off: supercapacitors operate at relatively very low voltages, with most rated between 2.7 and 3 V per cell, or even lower for aqueous-based electrolytes. In contrast, traditional capacitors, such as electrolytic capacitors, offer much lower capacitance but can function across a wide voltage range, from just a few volts to several thousand volts. These differences in capacitance and operating voltage highlight the unique roles of each technology in modern electronics. Another interesting difference between both technologies is their operating temperature range. Traditional capacitors can function over a broader temperature range from -55ºC to + 125ºC, compared to supercapacitors which are generally rated from -40ºC to +85ºC. Additionally, both technologies may require voltage derating at elevated temperatures, reducing their maximum voltage rating under such conditions. Supercapacitors have additional advantages, such as high power and energy density compared to the standard capacitors, thanks to their well-developed high-surface-area electrodes. EDLCs typically have an estimated lifetime of up to 1,000,000 cycles, while pseudocapacitors offer a shorter lifespan of fewer than 10,000 cycles due to the chemical reactions involved.3 Key Parameters for Component Selection During component selection, all capacitors and supercapacitors have inherent limitations that can affect the performance in certain applications. Therefore, it is essential to evaluate key characteristics to ensure optimal performance. Applications Across Industries Capacitors are indispensable across a wide range of industries, as power supply filtering, decoupling, and energy storage in low power systems. For instance decoupling capacitors, based on AECs, tantalum and ceramic capacitor technologies are vital for ensuring stable operation of electronic devices by acting as local energy reserves. They supply instantaneous current to components like integrated circuits while minimizing voltage fluctuations and suppressing noise, which helps maintain power integrity and reduces electromagnetic interference (EMI) in systems such as PCs, smartphones and automotive electronics. With the increasing complexity and speed of modern electronics, the strategic placement and evolution of decoupling techniques are vital for ensuring signal quality and overall system reliability.4,5 As electronics continue to downsize, the miniaturization of capacitors becomes essential for integration into smaller and more complex systems. Reducing their size is crucial to maintain or even improve their performance, reliability, power and energy. These advancements are key to the continued development of wearable devices, IoT applications and consumer electronics. For example, step-down DC-DC converters commonly used in laptops, smartphones and power supplies to regulate voltage levels for various components often utilize AECs and tantalum capacitors. Nevertheless, the growing adoption of Multilayer Ceramic Capacitors (MLCCs) highlights their potential to replace these two technologies owing to their smaller footprint (size and profile), improved capacitance and enhanced reliability.6 Another example of innovation is the increasing amount of MLCCs in 5G smartphones, with some high-end models incorporating over 1,000 units, demonstrating how capacitor technology continues to evolve to meet the demands of modern electronics.7 Supercapacitors are also gaining traction across various industries. In consumer electronics and IoT devices, they power smart utility meters, GPS trackers, and asset monitoring systems. Their long lifespan and ability to handle repeated charge-discharge cycles make them ideal for real-time clock (RTC) backup and memory preservation during power outages. Additionally, supercapacitors are used in medical devices to ensure backup power for alarms or emergency systems, providing a reliable safeguard in critical situations. In microgrids, supercapacitors contribute to voltage and frequency stabilization, peak load management, and overall grid resilience. Often deployed alongside batteries, hybrid solutions maximize performance by leveraging the strengths of both technologies.8 For large-scale energy applications, supercapacitors are widely used in grid stabilization and renewable energy systems, helping smooth fluctuations from wind and solar power sources. In the transportation sector, they play a key role in hybrid and electric vehicles, providing quick bursts of energy for acceleration and efficiently capturing energy during regenerative braking.2 The future of capacitors and supercapacitors is being shaped by advancements in materials, design and integration, driven by the growing demand for high energy storage, wider operating temperature ranges, miniaturization and sustainability. [2] K. Dissanayake and D. Kularatna-Abeywardana, “A review of supercapacitors: Materials, technology, challenges, and renewable energy applications,” J. Energy Storage, vol. 96, no. May, p. 112563, 2024, doi: 10.1016/j.est.2024.112563. [3] E. Pameté et al., “The Many Deaths of Supercapacitors: Degradation, Aging, and Performance Fading,” Adv. Energy Mater., vol. 13, no. 29, 2023, doi: 10.1002/aenm.202301008. [4] Wevolver, “Decoupling capacitors: Mastering power integrity in electronic design.” Available: https://www.wevolver.com/article/decoupling-capacitors-mastering-power-integrity-in-electronic-design. [Accessed: Feb. 22, 2025] [5] Intel, “Power integrity support resources.” Available: https://www.intel.com/content/www/us/en/support/programmable/support-resources/power/pow-integrity.html. [Accessed: Feb. 14, 2025] [6] TDK, “MLCC replacement guide.” Available: https://product.tdk.com/en/techlibrary/solutionguide/mlcc_replace-guide.html. [Accessed: Feb. 14, 2025] [7] Murata, “MLCCs for 5G smartphones: Key considerations.” Available: https://article.murata.com/en-global/article/mlcc-for-5g-smartphone-1. [Accessed: Feb. 14, 2025]. [8] A. Berrueta, A. Ursua, I. S. Martin, A. Eftekhari, and P. Sanchis, “Supercapacitors: Electrical Characteristics, Modeling, Applications, and Future Trends,” IEEE Access, vol. 7, pp. 50869–50896, 2019, doi: 10.1109/ACCESS.2019.2908558. Capacitors and Supercapacitors: Technology Overview and Future Trends

What is a capacitor?

Understanding Supercapacitors: Structure and Mechanism

Emerging Innovations in Capacitor and Supercapacitor Technology

In the P.CAP project we are working at the forefront of supercapacitor materials to improve the frequency response and high temperature tolerance of our devices. We expect to have working prototypes by late 2025. Stay connected to learn more, and if you found this white paper valuable, feel free to share your thoughts in the form below.

[1] J. Torki, C. Joubert, and A. Sari, “Electrolytic capacitor: Properties and operation,” J. Energy Storage, vol. 58, no. December 2022, p. 106330, 2023, doi: 10.1016/j.est.2022.10633].

This website uses cookies to improve your web experience.