C2C-NewCap Brings Safe, Reliable Power to Lviv Streets

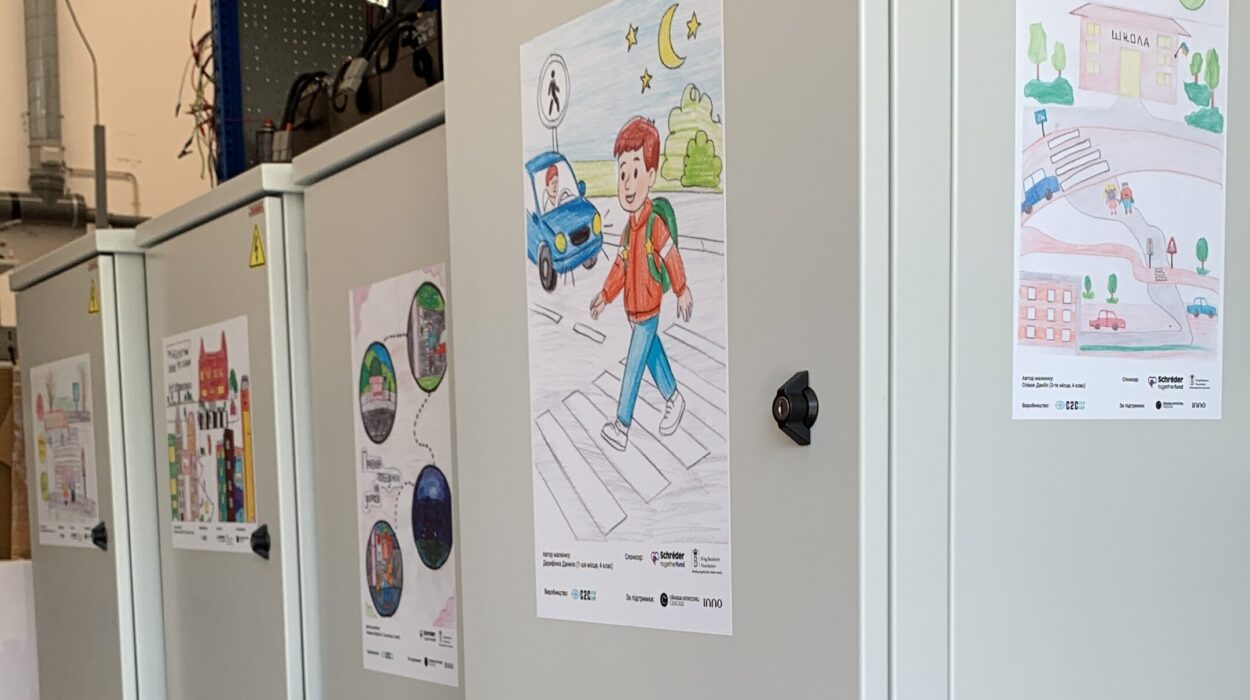

Where Energy Storage Meets Student Creativity to Brighten Lviv

We are currently involved in several national and EU-funded projects

We collaborate with several universities, R&D institutes and companies